Corporate Profile

Our Strengths

Our ability to provide what you want, when you want it, in the quantities you want, is a formidable capability.

We have three response capabilities:

Response to ‘when you want’ – the structure and facilities to provide a case-by-case response

Response to ‘what you want’ - a wide variety of product services

Response to ‘the quantity you want’ - a variety of production methods to match your needs, from small orders to bulk orders

We provide over 3,600 kinds of prototypes per annum to customers in a variety of markets and fields around the world.

Response capability: an asset in the prototype business

A flexible response to industries undergoing diversification

Making ‘when you want’ happen

The structure and facilities to provide a case-by-case response

Multi-skilled engineers

It is because each worker is able to handle everything from design to production and quality control that we are able to respond to ‘when you want it’.

A meticulous order-receipt system

Our FC (Factory Chain) enables us to provide ‘what you want’, ‘in the quantities you want’.

The launch of a workshop inspired by the image of a convenience store, led by Saijo Shisaku Studio.

At the present time, there are three Factory Chain workshops. We provide investment in the form of equipment, die systems, design software, etc., and undertake human resource development, while the FC workshops provide the location and staffing and run their companies: this is a mechanism that allows the workshops to expand without having to worry about fixed costs. Continued painstaking work to standardize production and to expand that standardization to the FC workshops has created a structure that enables production to take place under the same philosophy that we hold. This is the secret to our ability to respond flexibly even in the face of sudden workload fluctuations.

Making ‘in the quantities you want’ happen

Proposing the optimum method from a variety of blanks

Enlarge (PDF 62.7KB)

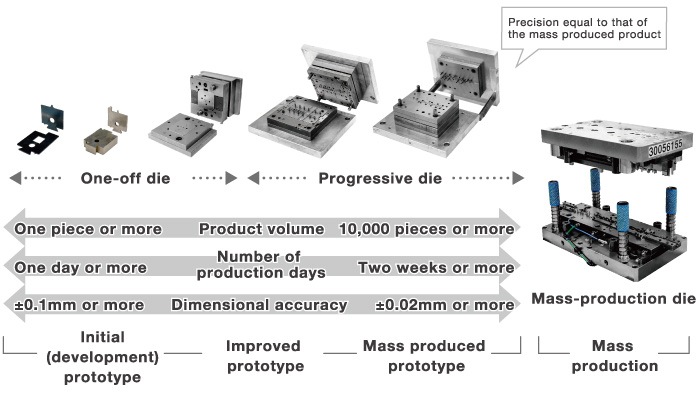

Proposing a variety of methods according to the development stage/quantity

Making the best choice for the work stage, from a single-item prototype to mass-produced prototype processing

A variety of production methods to match the needs

From simple items to high-reliability items, production using the optimum die

Our abundant array of equipment provides short delivery times, low cost and high quality

We are a leading prototype manufacturer of thin sheet metal and injection molding products, providing high quality products at low cost and to short deadlines. In order to succeed in the borderless business environment and to achieve even shorter deadlines, greater cost reductions, and increased quality, our manufacturing facilities are equipped with the most advanced machinery available.

Making ‘what you want’ happen

A varied process menu able to respond to ‘what you want’

Development Support of Thin Sheet Metal Fins from Development & Design to Prototyping

With analysis technology such like thermal fluid analysis, heat conduction analysis, stress analysis with using analysis tool, we simulate the products (design) at the conceptual stage and evaluate the characteristics of products and the directivity of improvement performance. Therefore, you can shorten the development cycle and reduce the development cost.

- Simulation・Design

-

- Checking the temperature distribution, thermal resistance & etc. by analysis of fins.

- Evaluation of unit to derive the optimum shape for satisfying the specification.

- Checking the locus of fluid, temperature distribution & etc.

- Saijo Standard Fins

-

- We have various standard fins, so you can try them easily, before you make customized prototypes.

- Standard fins that already evaluated the thermal resistance & pressure loss by natural air cooling & forced air cooling of in-house evaluation equipment.

- Available for lot production.

See the corporate site for details. ![]()

- Heat Exchanger

-

- You can confirm from completeness of parts to assembly.

- We can support in case of problems quickly. (You can confirm how you should modify the product immediately.)

- As well as the drawing, you can confirm the gauging.

- We can reduce the development cost and shorten the delivery time by 1 - 3

- We can reduce your man-days. (For example, order business, delivery date management, confirmation of parts quality after arrival of goods, and etc.) See the corporate site for details.

Prototype Fin Processing

Corrugated fin, offset fin, inner fin, louvered fin, waving fin, and slit fin processing

Your innovation partner for lightweight heat radiation fins (heat sink), heat sink and current collector fins!

- Reduced initial costs, short delivery time and high-precision using our Original Die-Sets System.

- Suggestions for product shape based on your conditions such as product function, performance, and cost.

- Suggestions for optimum product shape based on heat analysis simulations.

- High quality and high accuracy joining through our metal joining technologies.

See the corporate site for details. ![]()

Prototype - Microscopic/Superfine Thin Sheet Metal Processing

Conventionally, metal die-sets that are the same type as the mass production die-sets are manufactured when manufacturing microscopic/superfine prototypes. However, at Saijo INX, we have established new manufacturing technology for manufacturing prototypes that maintains the same level of quality as in mass production.

- Same quality level as in mass production.

- Our high-precision Original Die-Sets System achieves low costs and short delivery times.

- Inner processing of metal parts by graphical profile grinding.

- Thousands to tens of thousands of mass production prototypes can be manufactured from one principal prototype.

Prototype Metal/Die Set Processing

Our integrated manufacturing process enables us to provide everything from the design of injection molding dies through to manufacturing and molding, insert molding, and assembly processing with metal parts.

Conventionally, metal parts and molding parts were ordered separately from different companies. Our prototype molding department, however, can provide both metal and molding services together, thus reducing the amount of time required to create a prototype.

In particular, our exceptional technical skills enable insert molding, in which the strength of the sheet metal function, and mold cassette technology enables production to short delivery times.

We can also provide a complete manufacturing service, from press fitting manufactured metal and molding parts to insert molding and final assembly. By applying our skills and know-how in simple pressing of sheet metal to mold, we can respond to all of your prototype needs in-house.

Prototype-Round Bus Bar

Improving the space efficiency of products and attaching the insulation properties (insulating layer, surface treatment, thermal expansion tube, molding and etc.) are possible.

- Available for processing to φ2mm~10mm.

- Improving the material yield at mass-production stage.

- Providing the 3D shape bus bar.

- Available for processing the clamp face (surface) by crushing & mounting holes at the flattening part.

- No exclusive die-sets by using standard die-sets.

* Depending on the shape, exclusive die-sets are necessary. - Available for insert molding.

* As for round shape, separate consultation is required. - Available for processing copper & aluminum.

- Available for supporting your design.

* Electric properties, cross section, resistance against vibration, size & etc.) - Available for processing the sheet metal.

* Processing limitation of thickness is 3.0mm.

Prototype - Drawing Processing

Circular drawing, square drawing, complex shape drawing, deep drawing, drawing + ironing

We specialize in high precision, high accuracy drawing processing for such products as electronic components, battery components, medical and aerospace related components, weak electric current motor case components, shield case components, and sensor components.

- “We have produced a few prototypes by cutting, but want to use stamping (drawing processing), which is the same process as for mass production, to evaluate quality.”

- “We need lots of a few thousand units to make sample evaluations for mass production.”

- “Our deadline for mobile communication related components is extremely tight and the mass production die-sets won't be ready in time, so we want to use the prototype die-sets instead.”

- “We need prototypes in a short time span because we don't have much time for evaluation.”

- “We want to investigate whether we can change the manufacturing process for cutting parts to stamping.”

- “We want to check whether you can manufacture to our required precision.”

Please contact us!

See the corporate site for details. ![]()